Insights behind the scenes. How exactly does the new Jennerbahn work and how does it differ technically from the old one? We want to answer these questions today and give you an insight into the technology of the Jennerbahn.

“The old valley station was my birthplace, nursery and playground,” says our deputy operations manager Max Bosch. He is deeply rooted in the Jennerbahn, his father worked for over three decades as operations manager and board member at Berchtesgadener Bergbahn AG. Max therefore came into contact with the cable car at an early age. After vacation jobs and weekend work, he has been a permanent employee since 2006 and deputy operations manager since last year. He particularly enjoys the variety between office work and work in the field or in the workshop.

Max worked as a machine operator on both the old and the new Jennerbahn and was therefore able to experience the changes at first hand. He was therefore able to give us technical details in comparison with the old lift.

The route

Although the route of the two railroads is identical, the number of supports was greatly reduced. When the Jennerbahn was built in 1953, there was a requirement that the railroad line should not be recognizable as such. For this reason, the decision was made to use low green-painted supports. It also had to be possible to rescue the cabin from the ground. There were 43 tripod supports in total. In the new construction, these were replaced with 18 significantly higher round tube supports. This significantly lower number is sufficient, as the higher structures allow for longer cable spans (distance between two supports).

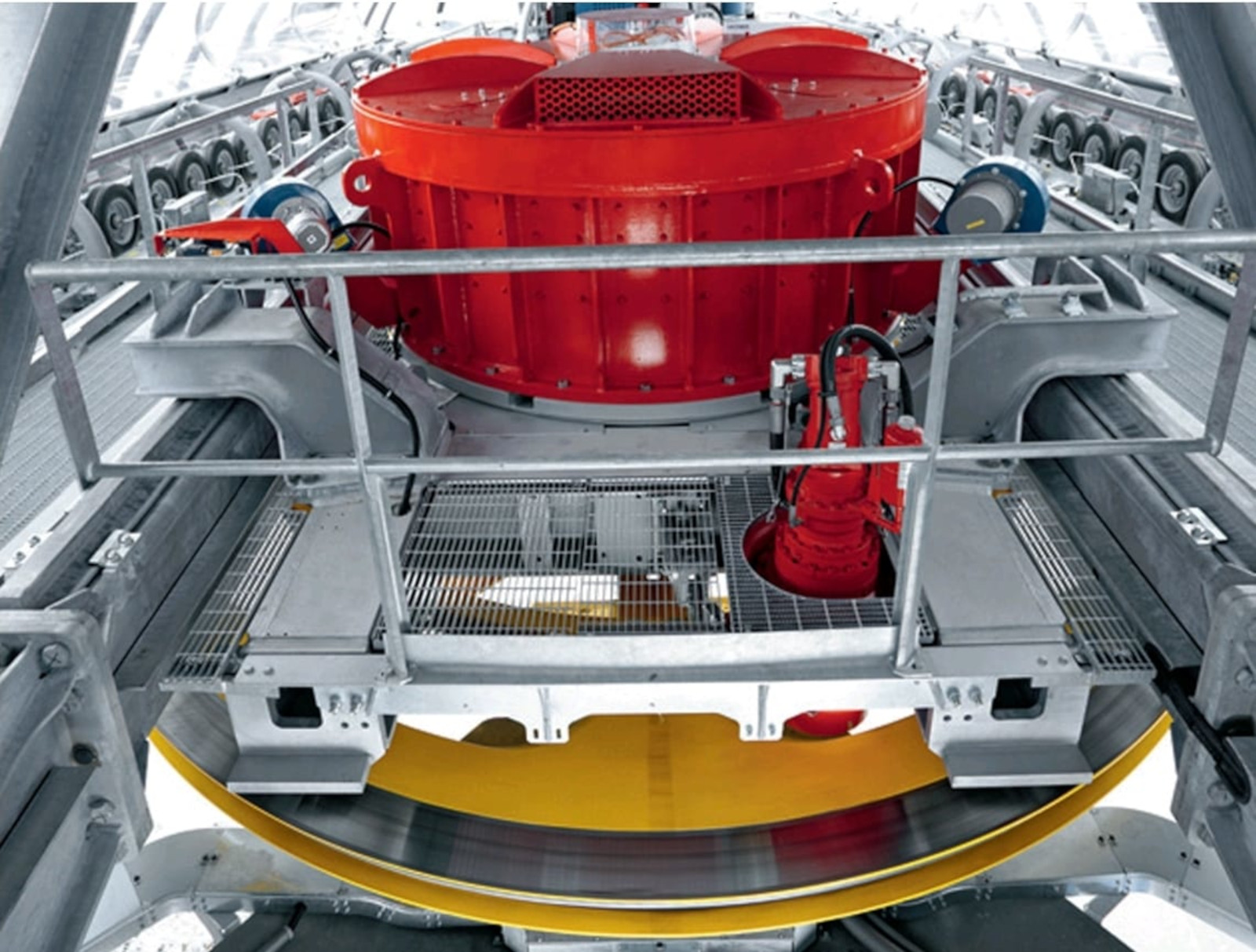

The drive

The Jennerbahn has two drives. These are low-speed three-phase motors whose drive shafts are directly connected to the rope sheave, making a gearbox and the associated costly maintenance unnecessary.

The drive of section 1 (bottom station – middle station) has an output of 590 kW (approx. 800 HP), while the drive of section 2 (middle station – mountain station) has an output of 610 kW (approx. 830 HP). This allows the Jennerbahn to accelerate continuously up to a speed of 6m/s (approx. 21km/h). In comparison, the old lift had an output of 147kW (approx. 197PS) on both sections and could reach a maximum speed of 3m/s.

The difference in performance is particularly noticeable in the travel time: in 2017, the journey from the valley to the mountain still took around 25 minutes. Today, it only takes around 11 minutes to cover the same distance at full speed.

The vehicles

The old Jennerbahn had 170 gondolas and eight special hangers, such as dragon, transport or work hangers. There was room for two people in each gondola, so that up to 480 people could be transported per hour.

The new lift, on the other hand, has 60 10-passenger cabins, a kite hanger, a transport gondola and a working hanger. The gondolas can be loaded with up to 800 kg, but could carry at least three times this load according to Max Bosch.

The clamp and the station run

Contrary to some assumptions, the gondolas on a monocable gondola lift such as the Jennerbahn do not move along the rope, but are clamped onto it.

Each clamp has two powerful springs that ensure that the gondolas are coupled to the rope with sufficient force. If one of the springs is no longer fully functional, the clamp still has sufficient hold thanks to the other. When passing through the station, the gondola is released from the rope by a coupling process and is then guided through the station circuit by conveyor tires on a running rail. In the exit area, the gondola is clamped back onto the rope via the coupling point.

The rope

As the namesake, the rope is probably the most important component of any ropeway.

The two ropes of the Jennerbahn have a diameter of 50mm and consist of 216 individual wires, which are made into 6 bundles, also known as strands, each consisting of 36 wires. To ensure that the rope holds together, it is spliced overlapping over a length of approx. 70m. “The whole thing resembles a braided plait,” explains Max Bosch.

Safety

The safetyof passengers is the top priority for every cable car. For this reason, all components of the Jennerbahn are checked monthly, many even daily, and replaced at regular intervals. In addition, every station and the entire route is equipped with monitoring devices. Any anomaly triggers a readjustment in the system or an automatic shutdown. In addition, each support is equipped with sensors to monitor the position of the rope. This would, for example, stop the track immediately in the event of an imminent derailment. Alternatively, the train operators on the platform always have the option of switching off the train via an emergency stop. In addition, the brakes are checked daily before the start of operation.

In the event of a drive failure, our guests do not have to stay in the gondola for long, as the emergency drive takes over. This is powered by diesel to bring guests safely down to the valley even in the event of a power failure.

The new construction of the Jennerbahn with its technical innovations has been inspiring and since its completion in 2018/19.

Almost silently up to 1,800m in 11 minutes…

…see you soon on the Jenner!